Typically, one of the first things you would want to have is the asset number field so that the clinical staff member can put that in. This page can be custom made to allow the clinical staff members to see exactly what they need to have in order to place a corrective maintenance work order. Once they click on the link, they will then be taken to a corrective maintenance request page, which actually resides within the computerized management system. The database manager or biomed staff member will need to create a page and put a link to it on the hospital’s Intranet page so that the internal clinical staff members can get to that link.

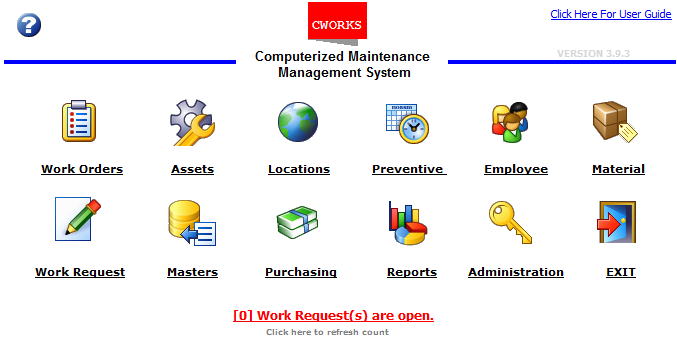

Once again, setting up this page can be done using a GUI interface. The creation of this interface would require a little bit of SQL knowledge perhaps, or it may be simple as drag and drop using a GUI interface that allows you to build another page specific for the call center staff.Īn additional workflow that can be set up within the computerized, maintenance management system for work order entry is to have yet another page set up for clinical staff to directly enter the work order into the database. It may be simple enough for the biomed staff member to create or maybe somebody who manages the database might be able to do it. The page that is set up for the call center staff can be created using the GUI interface that is available in the computerized, maintenance management system. It would be predetermined exactly what fields they would have access to view and what Fields they would be able to actually enter data into based on the call coming in.

One reason is that you do not want call center staff to be able to get pretty deep into the database and access data and or inadvertently change any data.įor this reason, a separate GUI interface can be set up through the computerized, maintenance management system so that when a call comes in the call center, the staff can create a corrective maintenance work order. Typically, for this kind of an entry, the biomed department would set up a separate GUI interface accessible to the call center staff.

#HOW A COMPUTERIZED MAINTENANCE MANAGEMENT SYSTEM WORKS SERIAL NUMBER#

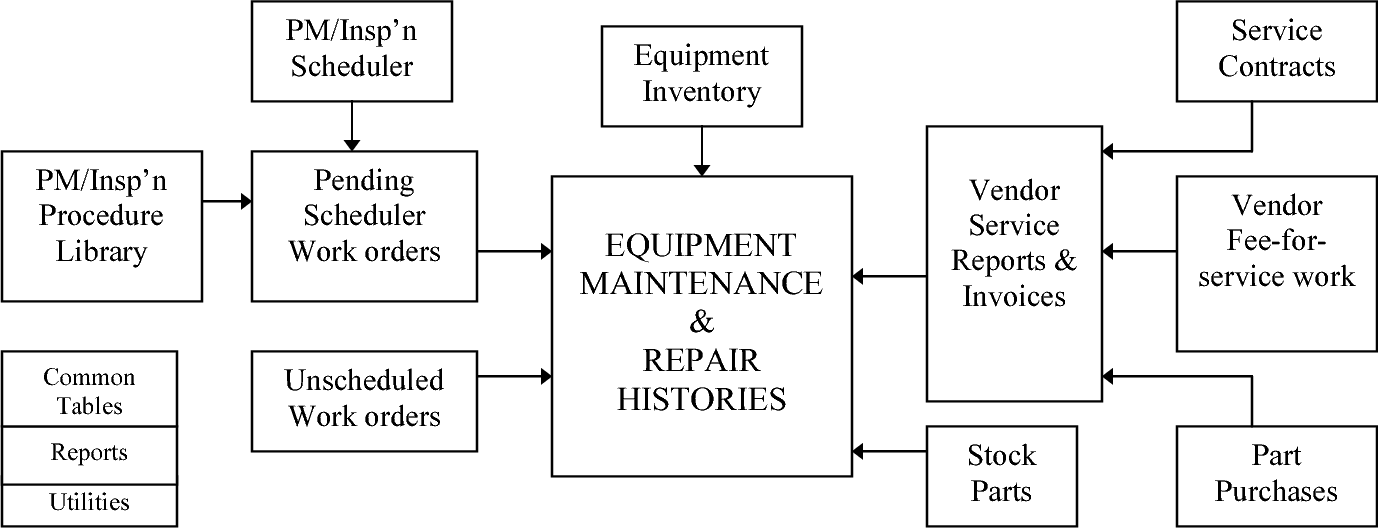

These fields would be everything from serial number to manufacturer and model information and much more as defined by the biomed department.Īnother workflow for how a corrective maintenance work order can be created within the computerized, maintenance management system is for the call center to enter the corrective call into the database. Typically, when the biomed staff member opens the application and enters the asset number in the work order creation section, the remaining pertinent fields should show up on the same page. This can be done using a GUI interface that sits in front of the tables that are stored in the server. One way that a corrective maintenance work order can be created within the computerized, maintenance management system is for the biomed staff member to create the work order themselves within the system against a particular asset record. All historical work orders must tell a story within the computerized, maintenance management system about the corrective maintenance that was done on an asset record since the time it came into the hospital system. This is a very important function that must be tracked and stored in the database for regulatory reasons within the hospital. The computerized, maintenance management system is very important in tracking and creating corrective maintenance work orders for an asset record. George Maliakal, in Careers in Biomedical Engineering, 2019 Corrective Maintenance (CM ) Work Orders and Flow It gives important indicators for the decision making in the maintenance management in order to attain the best possible usefulness of equipment and systems, as higher reliability in general leads to a lower operating cost. Birolini (2004) points out that reliability analysis is interrelated with cost and system effectiveness. Thus, the reliability analysis of a system provides information about its failure process, assisting in the comprehension of system operation and what to expect from its performance to better adjust the maintenance planning ( Barringer, 2004). According to Rausand and Hoyland (2004), with respect to a repairable system, the goal of maintenance is to restore it when necessary, but mainly to seek the improvement of the system reliability. The maintenance management is important to ensure the constant improvement of equipment performance, ensuring quality operating within safe conditions for people and the environment ( Jiang, 2015). Pessoa, in Computer Aided Chemical Engineering, 2018 1 Introduction

0 kommentar(er)

0 kommentar(er)